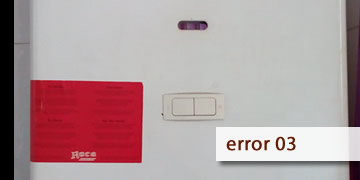

Roca 20 20 Boiler Error 03

Index of contents

What does this failure affecting the rock boiler mean?

When it comes to keeping the home warm, especially in the winter seasons, boilers play an essential role in our households. But as you know, they are devices that can develop faults that negatively affect their operation, including those from the Roca brand. Error code 03 is a message that indicates something is wrong with the boiler pressure. But this failure can be more than just a number; it's a warning sign for us to take action and prevent larger problems in the future.

This failure affecting Roca brand boilers is triggered when the device detects insufficient pressure inside the boiler for its correct operation. This can be due to various reasons, from a simple leak to a more complex problem with the safety valve. Identifying the exact cause of the problem is important so that you can find an appropriate solution, which is why we will now look at the possible causes of this problem:

- Low gas pressure: If the gas pressure is less than 1.5 bar, the boiler cannot operate properly. You will need to investigate why this pressure has decreased and correct the fault.

- Water leaks in the circuit: A water leak can reduce internal pressure and affect the boiler's performance, causing various errors to appear on its display.

- Defective circulation pump: A pump that is not functioning correctly can hinder proper water circulation throughout your boiler's circuit.

- Damaged safety valve: A faulty safety valve can release pressure and cause the error to appear on your boiler's display.

Now that we have the causes of this problem, let's see what solutions you can apply to continue using your Roca 20/20F boiler normally.

How can the failure 03 in the rock boiler 20 20 be fixed?

We have prepared for you a list of possible solutions to this fault that appears on your boiler's screen. Please take note of each of these steps, follow them to the letter, and do not skip any, as they are all important:

- Turn off and disconnect the boiler may help solve the problem, as the sensors of the boiler are reset: Let's start first with the easiest and simplest of all steps, which is to apply a boiler reset. To do this, you would need to completely turn off your boiler and disconnect it from the power outlet for a few minutes. Wait for at least 15 minutes and reconnect the boiler. Then turn it on and now check if this error has disappeared. If the problem persists, then you will have to continue with the other steps we leave you below.

- Check that the water supply is active and functioning at full capacity: Open the other taps in your home or office to check that you have the water supply activated. If you have a water supply interruption, contact the water company to confirm if the interruption was due to a billing issue or scheduled maintenance in your area. Also, check the shut-off valve that supplies water, both the general one for your entire home or office, and the one that supplies only the boiler. If these valves are halfway open, please open them fully so that the water supply is smooth and constant to your boiler.

- Adjust the water and gas pressure to ensure they are set according to the manufacturer's specifications: Check that the water and gas pressure are correct, it may be lacking pressure and you may need to adjust the pressure gauge for it. This pressure must be (according to the Roca manufacturer) at 1.5 bar. But these values could change depending on the model and capacity of your boiler, so check the manufacturer's manual carefully before making changes of this type and changes in pressures, both of water and gas. Once you have corrected the pressures, check if the error has disappeared from your boiler.

- Check the circulation pump of your Roca boiler: Make sure the pump is working properly and is not blocked by anything. If necessary, disassemble it from the boiler and perform preventive maintenance. If you have knowledge in electronics, check it with a multimeter and make sure it has good continuity in the connection to the PCB electronic board of your boiler. Also, check that the wiring that communicates this pump is in excellent condition.

- Check the safety valve of your Roca boiler: Make sure the valve is not releasing unnecessary pressure and/or leaking. If the valve is damaged, you will have to replace it with a new one, but before that, you can try to do a small preventive maintenance to see if you can recover it. Disassemble the valve and clean it with water and a little vinegar, use a bristle brush to clean it well, especially in the holes. Let it dry well and proceed to assemble it back into your Roca boiler. Now check if with this procedure you have been able to fix the fault.

- Check the entire water circuit of your boiler for unwanted leaks: Make sure the boiler does not have any type of leak in the entire water circuit. To be able to check this, you have to check absolutely everything related, and we mean hoses, seals, connections, filters, and valves. Check everything and if you find any type of leak, make the necessary repairs or replace the components and parts affected by new ones to prevent leaks in the future.

- If the problem with your boiler persists, carefully review each step we have explained in this article: You don't have to be discouraged, make sure you have not omitted any of the steps we have mentioned in this advice guide. If you still cannot find the solution, it is time to consult with an expert in the field who can help you. A qualified professional or Roca's official technical service can help you diagnose and solve the problem accurately.

- The experts may have the right solution to your problem, give a call to Roca's technical support: A qualified technician or Roca's official technical service can help you solve the fault of your boiler in record time. We are sure that they have the necessary experience and knowledge, along with the tools and original spare parts to address this situation in the best possible way, ensuring an effective repair. You can contact them by phone and schedule an appointment for them to visit you at home. Don't hesitate to seek professional help to get your boiler back to working properly!

To summarize and conclude, in order to fix the fault of error code 03 in Roca 20/20F boilers, you have to follow all the steps we have explained in this advice guide. This fault is due to low pressure in the boiler circuit, and its causes can be the following: low gas pressure, water leakage in the circuit, damaged circulation pump, and/or the safety valve that is damaged or dirty.

Usually, this type of fault occurs in Roca boilers when they are newly installed and need to adjust the pressure to reach an adequate level. Although it could also occur in boilers that have maintenance issues. Remember that if you cannot solve the problem by yourself, you can always rely on Roca's technical support to find the solution to this problem. Thank you very much for reading us this far, and good luck with the repairs!