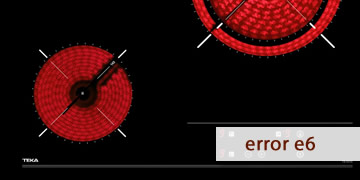

E6 error on Teka induction hobs

Table of contents

What usually triggers the E6 error on a Teka induction hob

The E6 error on a Teka induction hob typically points to an internal electronics issue related to the hob’s power supply section (internal voltages not within range) and, in some cases, factors that affect cooling or thermal readings. In other words: the hob decides it cannot operate reliably and locks out to protect the power stage.

This code often appears with fairly recognisable patterns:

- The hob powers up, tries to start a zone, then stops and shows E6.

- It appears after a power cut, repeated micro-outages, or a major voltage fluctuation.

- It shows up after some time in use and returns more often when the hob has poor cabinet ventilation (tight cut-out, oven below running hot, blocked vents).

- Sometimes it is intermittent: it works “for a while” and then locks again.

From a troubleshooting point of view, E6 is most often associated with:

- Internal supply/power-stage abnormalities (auxiliary rails out of range or power-stage monitoring detecting a fault).

- Filter board / power module deterioration (common when the error repeats regardless of usage).

- Insufficient cooling or thermal conditions that destabilise the electronics (restricted airflow, underperforming fan, etc.).

That is why E6 is commonly treated as an “electronics” error: sometimes a reset plus better ventilation is enough, but frequent recurrence usually calls for a proper service check.

What to do to clear the E6 error step by step

Important: an induction hob contains mains voltage and sensitive components. Do not open it unless you are qualified. The steps below are safe and help you fix the common causes—or narrow the issue down.

- Perform a full electrical reset

- Switch the hob off from the touch panel.

- Turn the hob circuit breaker off for 3 minutes (not 10 seconds).

- Restore power and test a single zone at medium power.

This clears lockouts that can remain latched after a one-off supply anomaly.

- Reduce variables: test without high demand

- Do not use Boost during testing.

- Avoid turning on multiple zones at the same time.

- If E6 appears even at medium power, the issue is less “usage-related” and more “electronics/supply-related”.

- Check cabinet ventilation (very relevant for electronics-type errors)

- Make sure the cabinet air inlets/outlets are not blocked.

- Remove objects from the drawer below if they are pressed against the hob base.

- If an oven is installed underneath, avoid running oven + hob at maximum load for long continuous periods.

A hob with restricted airflow can operate at the limit and trigger recurring errors.

- Notice whether E6 appears “cold” or after a few minutes

- Immediately, from cold: more suggestive of internal supply, filter board, or power module.

- After some minutes: thermal influence is more likely (cooling/fan/temperature around the electronics).

- If E6 started after installation or electrical changes, have the wiring checked

- Confirm the hob is wired to the correct configuration for the model (230 V single-phase or 400 V 2N if applicable).

- Ensure bridging links are correct and terminal screws are properly tightened.

- Make sure the hob circuit is not experiencing voltage drops due to heavy shared loads.

An irregular supply can trigger electronics errors even when the hob itself is not “bad”.

- When it’s best to stop and call service

- E6 returns after a full reset and with ventilation clearly improved.

- The error appears repeatedly even without demanding high power.

- You notice clicking, a burning smell, or abrupt shutdowns.

At that point, the usual focus is the filter board, power module and/or the internal supply rails. Those checks require measurements and internal access, so a qualified technician is recommended.

- Tips to reduce the chance of it returning

- Keep cabinet ventilation paths clear and avoid “boxing in” the hob.

- If your area has frequent micro-outages/spikes, consider appropriate protection at the electrical panel (per local regulations).

- If the fault is intermittent, act early: electronics issues tend to worsen over time.

If E6 was a one-off event after a supply fluctuation, it may stay as an isolated incident. If it becomes recurrent, resolving it typically requires proper diagnosis of the electronics stage (filter/power module/internal supply) to restore stable operation.